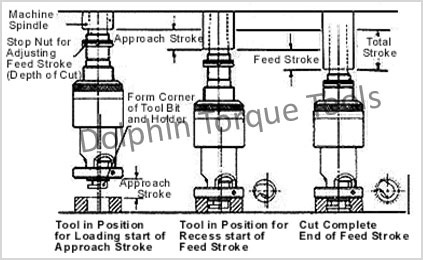

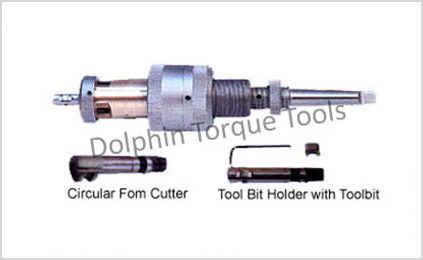

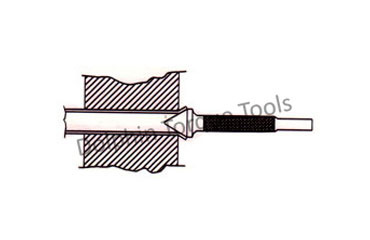

"Dolphin" Automatic Grooving Tool besides Catering to various Applications for Internal Grooving is specially deigned for Machining Grooves in Tube Sheet Holes to aid in Locking Rolled Tubes into Position during Tube Expansion.

• Changing of pilot nose and cutter allows one tool to cover a range of hole diameters.

• Simple to change cutter for different groove shapes.

• Location and depth for cut easy to adjust.

• Only light pressure required to cut precision grooves.

• Ready to fit CNC drill machiones, lathes and boring machines.

• The life of cutter extendable by resharpening.

| Bore Range | Tool Model No. | Pilot Nose Model No. | Circular From Cutter Model No. | Tool Bit Holder Model No. | Spare Tool Bit Model No. | |

|---|---|---|---|---|---|---|

| mm | inch | |||||

| 9 - 32 | 3/8 - 1.1/4 | 1 NW - 2 MT | 1 NW - PN | 1 NW - CF | 1 NW - TBH | 1 NW TB |

| 16 - 45 | 5/8 - 1.3/4 | 2 NW - 3 MT | 2 NW - PN | 2 NW - CF | 2 NW - TBH | 2 NW TB |

| 19 - 48 | 3/4 - 1.7/8 | 4 NW - 4 MT | 4 NW - PN | 4 NW - CF | 4 NW - TBH | 4 NW TB |

| 38 -102 | 1.1/2 - 4 | 6 NW - 5 MT | 6 NW - PN | 6 NW - CF | 6 NW - TBH | 6 NW TB |

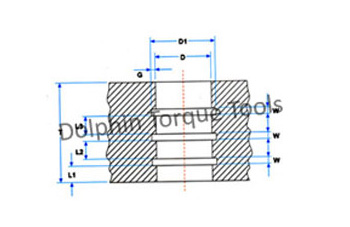

• Bore Dia after reaming with Tolerances : D

• Tube Plate Thickness : T

• Distance of First Groove : L1

• Total Number of Grooves : N

• Spacing of Grooves : L 2, L 3

• Groove Width : W

• Diameter of Grooves : D1

• Groove undercut Depth : G

• High speed steel, cryogenically treated & coated with titanuim Nitride for long life.

• Ideal for heat exchanger and tube sheet reaming.

• Reamers availabele in MM size also.

• For larger Diameters , please enquire.

| Tube O.D. | Reamer Size to "TEMA" Specification | Model No. | Flute Length | OAL | Shank: Morse Taper # | ||||

| mm | inch | mm | inch | mm | inch | mm | inch | ||

| 9.53 | 3/8 | 9.65 | .380 | RM-095/66 | 66 | 2.60 | 146 | 5.70 | 1 |

| RM-095/101 | 101 | 3.97 | 181 | 7.12 | |||||

| RM-095\152 | 152 | 5.98 | 232 | 9.13 | |||||

| 12.70 | 1/2 | 12.83 | .505 | RM-127/76 | 76 | 2.99 | 156 | 6.14 | 1 |

| RM-127/101 | 101 | 3.97 | 181 | 7.12 | |||||

| RM-127/152 | 152 | 5.98 | 232 | 9.13 | |||||

| 15.87 | 5/8 | 16.03 | .631 | RM-158/87 | 87 | 3.42 | 187 | 7.36 | 2 |

| RM-158/152 | 152 | 5.98 | 252 | 9.92 | |||||

| RM-158/203 | 203 | 7.99 | 303 | 11.93 | |||||

| 16.00 | - | 16.16 | .636 | RM-160/87 | 87 | 3.42 | 187 | 7.36 | 2 |

| RM-160/152 | 152 | 5.98 | 252 | 9.92 | |||||

| RM-160/203 | 203 | 7.99 | 303 | 11.93 | |||||

| 19.05 | 3/4 | 19.25 | .758 | RM-190/100 | 100 | 3.90 | 200 | 7.87 | 2 |

| RM-190/152 | 152 | 5.98 | 252 | 9.92 | |||||

| RM-190/203 | 203 | 7.99 | 303 | 11.93 | |||||

| 20.00 | - | 20.20 | .795 | RM-200/100 | 100 | 3.90 | 200 | 7.87 | 2 |

| RM-200/152 | 152 | 5.98 | 252 | 9.92 | |||||

| RM-200/203 | 203 | 7.99 | 303 | 11.93 | |||||

| 22.00 | - | 22.22 | .875 | RM-220/107 | 107 | 4.21 | 207 | 8.15 | 2 |

| RM-220/152 | 152 | 5.98 | 252 | 9.92 | |||||

| RM-220/203 | 203 | 7.99 | 303 | 11.93 | |||||

| 22.22 | 7/8 | 22.42 | .883 | RM-222/107 | 107 | 4.21 | 207 | 8.15 | 2 |

| RM-222/152 | 152 | 5.98 | 252 | 9.92 | |||||

| RM-222/203 | 203 | 7.99 | 303 | 11.93 | |||||

| 25.00 | - | 25.25 | .994 | RM-250/115 | 115 | 4.53 | 242 | 9.53 | 3 |

| RM-250/203 | 203 | 7.99 | 330 | 12.99 | |||||

| RM-250/254 | 254 | 10.00 | 381 | 15.00 | |||||

| 25.40 | 1 | 25.65 | 1.010 | RM-254/115 | 115 | 4.53 | 242 | 9.53 | 3 |

| RM-254/203 | 203 | 7.99 | 330 | 12.99 | |||||

| RM-254/254 | 254 | 10.00 | 381 | 15.00 | |||||

| 28.57 | 1.1/8 | 28.86 | 1.136 | RM-285/124 | 124 | 4.88 | 251 | 9.88 | 3 |

| RM-285/203 | 203 | 7.99 | 330 | 12.99 | |||||

| RM-285/254 | 254 | 10.00 | 381 | 15.00 | |||||

| 31.75 | 1.1/4 | 32.07 | 1.262 | RM-317/133 | 133 | 5.23 | 293 | 11.53 | 4 |

| RM-317/203 | 203 | 7.99 | 363 | 14.29 | |||||

| RM-317/254 | 254 | 10.00 | 414 | 16.30 | |||||

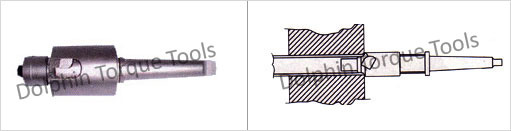

• High Production Tool

• Ideal For Tool where 1 Tool is need per bore

• One piece cryogenically treated tool bit ensures maximum life

• Tool is ideally suited for CNC applications on account of 1 piece mandrel construction and short design.

| Tube O.D. | Tool Model No. | Spare Tool Bits | |||

| mm | inch | 1/8" x 3/8" x 1/8" | 1/8" x 1/4" x 1/8" | Special | |

| Spacing | Spacing | Spacing | |||

| 9.53 | 3/8 | ST-375-970 | ST-3703 | ST-3703-S | ST-3703-SPEC |

| 12.70 | 1/2 | ST-500-1270 | ST-5003 | ST-5003-S | ST-5003-SPEC |

| 15.87 | 5/8 | ST-625-1588 | ST-6203 | ST-6203-S | ST-6203-SPEC |

| 19.05 | 3/4 | ST-750-1900 | ST-7503 | ST-7503-S | ST-7503-SPEC |

| 22.22 | 7/8 | ST-875-2220 | ST-7503 | ST-7503-S | ST-7503-SPEC |

| 25.40 | 1 | ST-1000-2540 | ST-7503 | ST-7503-S | ST-7503-SPEC |

| 31.75 | 1.1/4 | ST-1250-3175 | ST-7503 | ST-7503-S | ST-7503-SPEC |

| 38.10 | 1.1/2 | ST-1500-3810 | ST-7503 | ST-7503-S | ST-7503-SPEC |

| 50.80 | 2 | ST-2000-5080 | ST-7503 | ST-7503-S | ST-7503-SPEC |

| 63.50 | 2.1/2 | ST-2500-6350 | ST-7503 | ST-7503-S | ST-7503-SPEC |

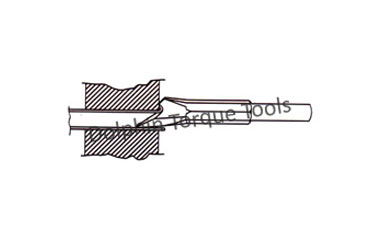

• Only light pressure required to cut pression grooves inside holes or cylinders.

• Location and depth of grooves easy to adjust.

• Simple to changes cutter from different grooves shapes.

• Changing of bushing and cutter allows one tool to cover a range of hole diameters.

• The life of cutter extendable by resharpening.

| Bore Range | Tool Model No | Pilot Nose / Bushing Model No. | Tool Bits Model No | |

| mm | inch | |||

| 10 - 13 | 0.40 - 0.51 | SGT - 102 | SGT - 102 - PN | SGT - 102 - TB |

| 12.7 - 16 | 0.50 - 0.63 | SGT - 122 | SGT - 122 - PN | SGT - 122 -TB |

| 16 - 20 | 0.63 - 0.79 | SGT - 162 | SGT - 162 - PN | SGT - 162 - TB |

| 19 - 32 | 0.75 - 1.26 | SGT - 193 | SGT - 193 - PN | SGT - 162 - TB |

| 30 - 52 | 1.18 - 2.05 | SGT - 303 | SGT - 303 - PN | SGT - 303 - TB |

| 50 - 78 | 1.97 - 3.07 | SGT - 504 | SGT - 504 - PN | SGT - 504 - TB |

•High speed steel tool used in preparing tube sheets to suit the flaring or beading of tube ends outside of or flush with the tube sheet.

• MM sizes and cutters with other radii are also available

| Tube O.D. | Model No. | Tool Radius |

Morse Taper inch |

|||

| mm | inch | mm | mm | |||

| 12.70 | 1/2 | 20338 | 3.2 | 12.70 | 1/2 | |

| 15.87 | 5/8 | 20224 | 4.0 | 15.87 | 5/8 | |

| 19.05 | 3/4 | 20225 | 4.8 | 19.05 | 3/4 | |

| 22.22 | 7/8 | 20226 | 4.8 | 22.22 | 7/8 | |

| 25.40 | 1 | 20227 | 4.8 | 25.40 | 1 | |

TEF Series

• Tools bits coated with Titanium Nitride to give 3 times the life of convertional tool bits.

•Ideal for quick facing of projecting tube ends in heat exchange condenser and boilers.

• One size of tool is suitable for use on multiple tube thicknesses by interchanging pilot.

• (TEF-375 is the exception with the tool suitable for one tube ID only.)

• Each tool is suplied with a set of multiple to cover all thicknesses.

• Tube and facers for MM size of tube also available.

| Tube O.D. | Tube Thk. bwg | Spare Tool Bits | |||

| mm | inch |

|

Model No. | Non-Ferrous or Carbon | Steel Tubes Model No. |

| mm | inch |

|

|

mm | inch |

| 9.53 | 3/8 | 16-22 | TEF-375 | TEF-376 | TEF-376 SS |

| 12.07 | 1/2 | 15-20 | TEF-500 | TEF-506 | TEF-506 SS |

| 15.87 | 5/8 | 14-18 | TEF-625 | TEF-626 | TEF-626 SS |

| 19.05 | 3/4 | 10-18 | TEF-750 | TEF-756 | TEF-756 SS |

| 22.22 | 7/8 | 13-18 | TEF-875 | TEF-876 | TEF-876 SS |

| 25.40 | 1 | 11-18 | TEF-1000 | TEF-1006 | TEF-1006 SS |

| 28.57 | 1.1/8 | 11-18 | TEF-1125 | TEF-1126 | TEF-1126 SS |

| 31.75 | 1.1/4 | 11-18 | TEF-1250 | TEF-1256 | TEF-1256 SS |

| 34.92 | 1.3/8 | 11-18 | TEF-1375 | TEF-1376 | TEF-1376 SS |

| 38.10 | 1.1/2 | 11-18 | TEF-1500 | TEF-1506 | TEF-1506 SS |

| 41.27 | 1.5/8 | 11-18 | TEF-1625 | TEF-1626 | TEF-1626 SS |

| 44.45 | 1.3/4 | 11-18 | TEF-1750 | TEF-1756 | TEF-1756 SS |

| 47.62 | 1.7/8 | 11-18 | TEF-1875 | TEF-1876 | TEF-1876 SS |

| 50.80 | 2 | 11-18 | TEF-2000 | TEF-2006 | TEF-2006 SS |

| 57.15 | 2.1/4 | 11-18 | TEF-2250 | TEF-2256 | TEF-2256 SS |

| 63.50 | 2.1/2 | 11-18 | TEF-2500 | TEF-2506 | TEF-2506 SS |

• High speed production tool.

• Titanium Nitride coated tool bit can be reversed and used. Double tool bit life.

| Tube O.D. | Tube Thk. bwg |

Model No | Spare Tool Bits | ||

| mm | inch | Non-Ferrous or Carbon Steel Tubes Model No. |

Stainless Steel Tubes Model No | ||

| 9.53 | 3/8 | 16-22 | FB-375 | FB-376 | FB-376 SS |

| 12.07 | 1/2 | 15-20 | FB-500 | FB-506 | FB-506 SS |

| 15.87 | 5/8 | 14-18 | FB-625 | FB-626 | FB-626 SS |

| 19.05 | 3/4 | 10-18 | FB-750 | FB-756 | FB-756 SS |

| 22.22 | 7/8 | 13-18 | FB-875 | FB-876 | FB-876 SS |

| 25.40 | 1 | 11-18 | FB-1000 | FB-1006 | FB-1006 SS |

| 28.57 | 1.1/8 | 11-18 | FB-1125 | FB-1126 | FB-1126 SS |

| 31.75 | 1.1/4 | 11-18 | FB-1250 | FB-1256 | FB-1256 SS |

| 34.92 | 1.3/8 | 11-18 | FB-1375 | FB-1376 | FB-1376 SS |

| 38.10 | 1.1/2 | 11-18 | FB-1500 | FB-1506 | FB-1506 SS |

| 41.27 | 1.5/8 | 11-18 | FB-1625 | FB-1626 | FB-1626 SS |

| 44.45 | 1.3/4 | 11-18 | FB-1750 | FB-1756 | FB-1756 SS |

| 47.62 | 1.7/8 | 11-18 | FB-1875 | FB-1876 | FB-1876 SS |

| 50.80 | 2 | 11-18 | FB-2000 | FB-2006 | FB-2006 SS |

| 57.15 | 2.1/4 | 11-18 | FB-2250 | FB-2256 | FB-2256 SS |

| 63.50 | 2.1/2 | 11-18 | FB-2500 | FB-2506 | FB-2506 SS |

• Tool uses 3 cutting blades which can be configured for tube end facing or weld removel as a step in the removel of welded tubes from tube sheet.

• Tool fitted with MT shank for use with standard air or electric drills.

• Cutting blades are Titanium Nitride coated to give 3 times the life of conventional cutting blades.

• Tools available for MM sizes of tubes also.

• Ideally suited for work on larger diameter boiler tubes.

| Tube O.D. | Facer Fitted With 3 Tool Bits Model No. | Spare Tool Bits Model No. | |

| mm | inch | ||

| 38.10 | 1.1/2 | FC-1500 | FC-1500-TB |

| 41.27 | 1.5/8 | FC-1625 | FC-1625-TB |

| 44.45 | 1.3/4 | FC-1750 | FC-1750-TB |

| 47.62 | 1.7/8 | FC-1875 | FC-1875-TB |

| 50.80 | 2 | FC-2000 | FC-2000-TB |

| 57.15 | 2.1/4 | FC-2250 | FC-2250-TB |

| 63.50 | 2.1/2 | FC-2500 | FC-2500-TB |

| 69.85 | 2.3/4 | FC-2750 | FC-2750-TB |

| 76.20 | 3 | FC-3000 | FC-3000-TB |

| 82.55 | 3.1/4 | FC-3250 | FC-3250-TB |

| 88.90 | 3.1/2 | FC-3500 | FC-3500-TB |

| 95.25 | 3.3/4 | FC-3750 | FC-3750-TB |

| 101.6 | 4 | FC-4000 | FC-4000-TB |

| Tube O.D. | Tube Thk. bwg | Model No. | |

| mm | inch | ||

| 12.70 | 1/2 | 16-22 | FT-1 |

| 15.87 | 5/8 | 14-15 | FT-2 |

| 16-22 | FT-3 | ||

| 19.05 | 3/4 | 14-15 | FT-4 |

| 16-22 | FT-5 | ||

| 22.22 | 7/8 | 14-15 | FT-6 |

| 16-22 | FT-7 | ||

| 25.40 | 1 | 12-15 | FT-8 |

| 16-22 | FT-9 | ||

| 28.57 | 1.1/8 | 12-15 | FT-10 |

| 16-22 | FT-11 | ||

| 31.75 | 1.1/4 | 8-14 | FT-12 |

| 15-22 | FT-13 | ||

| 34.92 | 1.3/8 | 8-14 | FT-14 |

| 15-22 | FT-15 | ||

| 38.10 | 1.1/2 | 8-14 | FT-16 |

| 15-22 | FT-17 | ||

| Tube O.D. | Tube Thk. bwg | Model No. |

|

| mm | inch | ||

| 12.70 | 1/2 | 16-17 | BDT-1 |

| 18-19 | BDT-2 | ||

| 20-22 | BDT-3 | ||

| 15.87 | 5/8 | 16-17 | BDT-4 |

| 18-19 | BDT-5 | ||

| 20-22 | BDT-6 | ||

| 19.05 | 3/4 | 16-17 | BDT-7 |

| 18-19 | BDT-8 | ||

| 20-22 | BDT-9 | ||

| 22.22 | 7/8 | 16-17 | BDT-10 |

| 18-19 | BDT-11 | ||

| 20-22 | BDT-12 | ||

| 25.40 | 1 | 16-17 | BDT-13 |

| 18-19 | BDT-14 | ||

| 20-22 | BDT-15 | ||

In many condensers the inlet end of tubes are required to be seated into the sheet. The contour is a "Bell End" or "Trumpet Mouth" of special shape